Industrial Image Processing

Image processing systems allow machines to see via industrial digital cameras and highly developed software algorithms. This opens up fascinating new possibilities for automation.

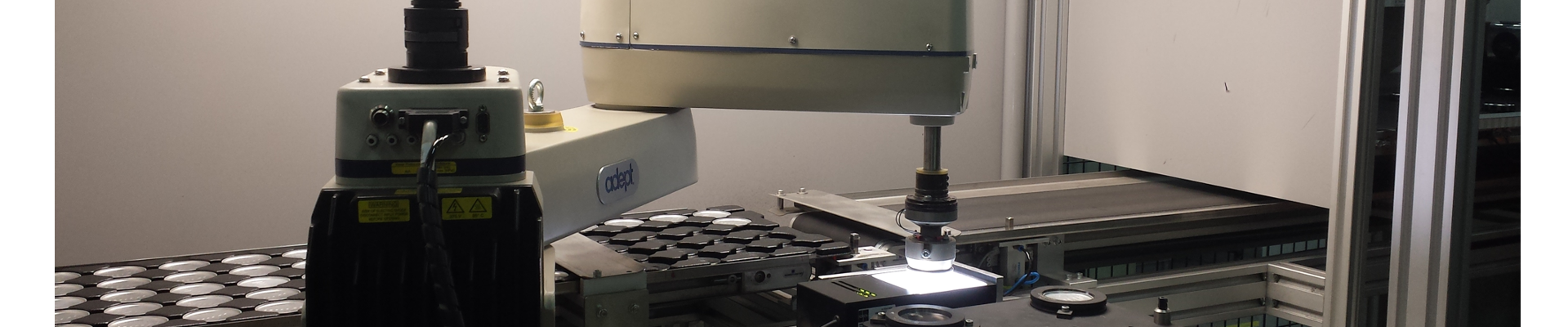

Quality and output are increased through advantageously applied camera technology combined with robot and servo drive technology. Digitization allows for seamless traceability.

When it comes to controlling the existence and completeness of work pieces, industrial camera systems are in action tirelessly. Today, vision technology also provides reliable support for object measurement and surface inspection.

In contrast to the human eye, digital image processing allows a permanent storage of image data and thus a backtracking of quality. In this case, the camera is superior to the human eye.

Image processing systems are successfully used in quality management. Following recurring patterns, the quality of products is measured and assessed through nondestructive testing.

A high degree of rationalization and consistent quality are achieved by automatic object measurement.

Object Recognition

In many areas of automation, digital industrial cameras help identify objects. The identification of components takes place via shape and appearance or via a coding system.

The use of such systems is not tied to a certain position and often takes place in ongoing production processes.

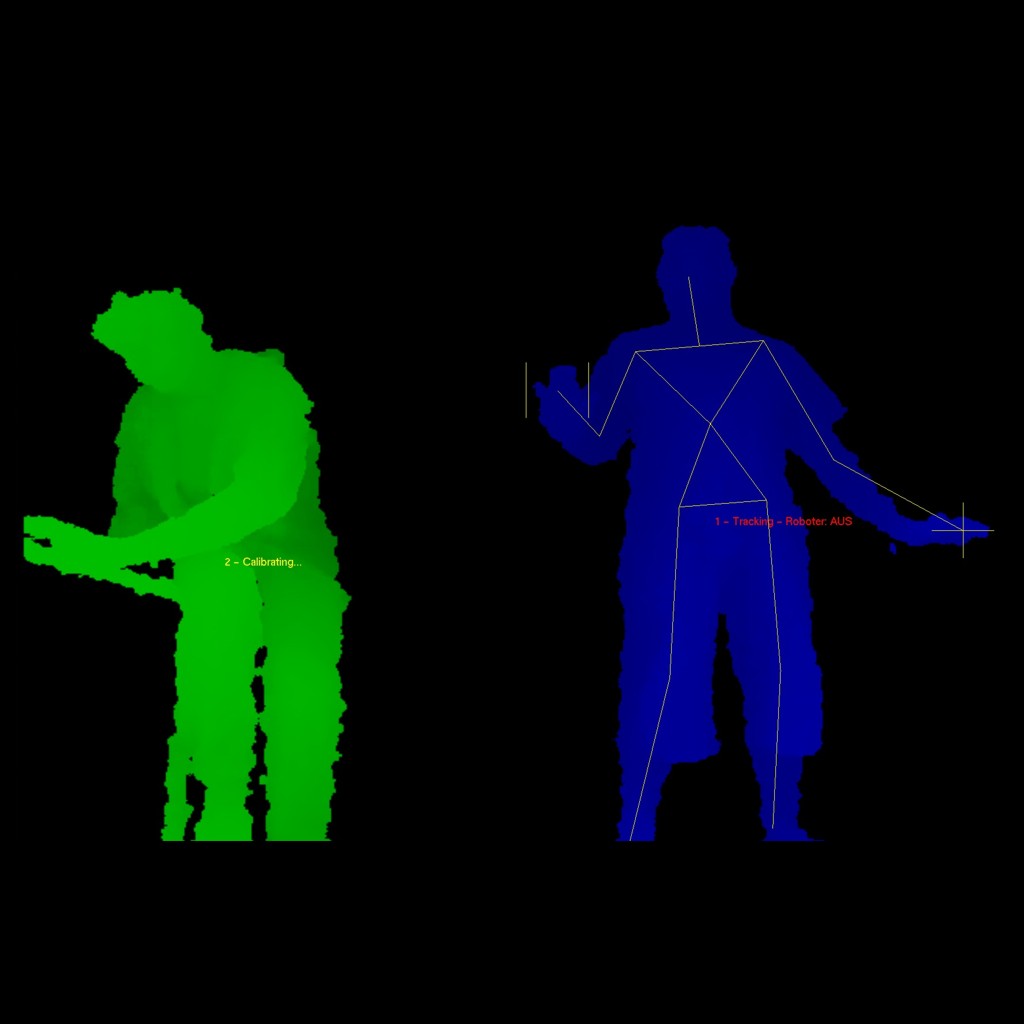

A special application is the recognition and tracking of moving objects. This requires a high error tolerance of the control system. A working example is the remote control of robots by human gestures.

Camera systems are a fixed component in our automation solutions. We use the technology consistently to automate operational procedures. For this, we rely on our own in-house developments.

Through gesture control, we combine human fine motor skills with the power and capacity of a machine.

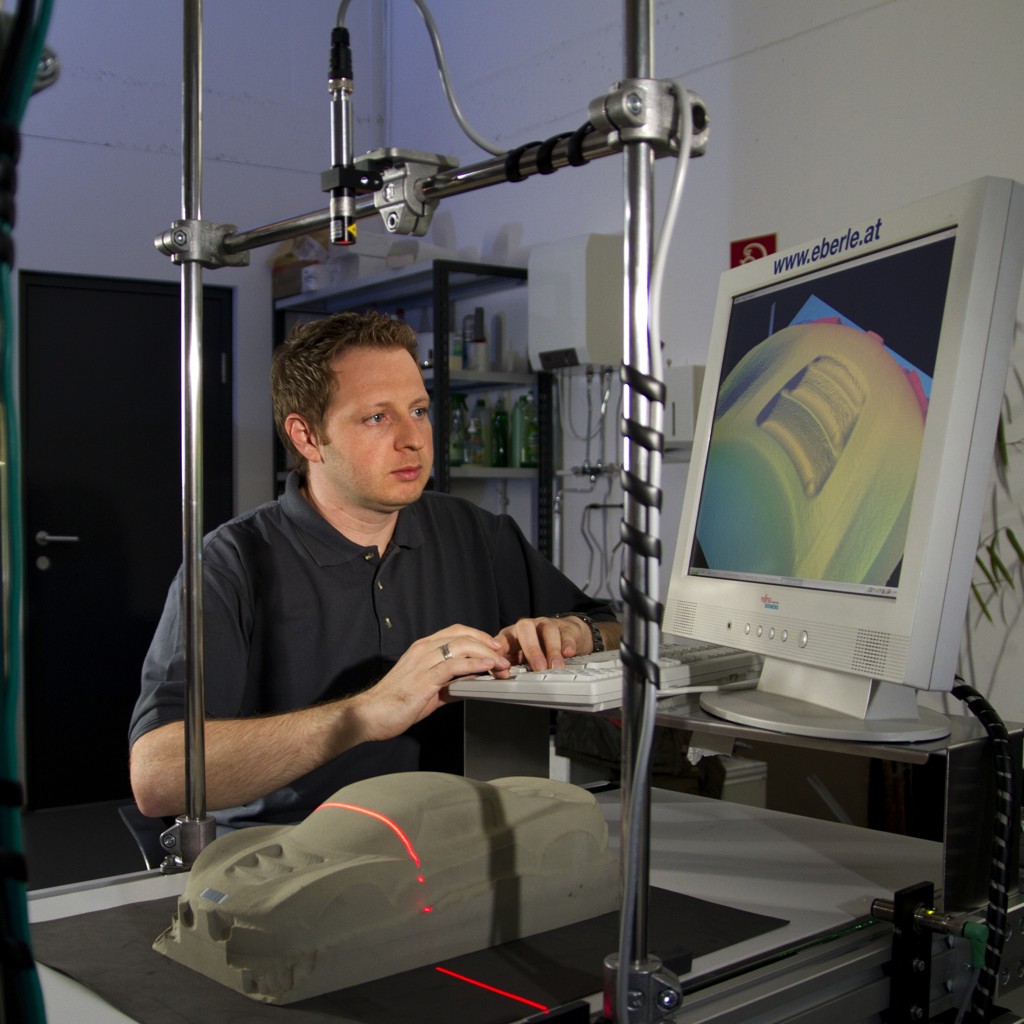

Surface Inspection

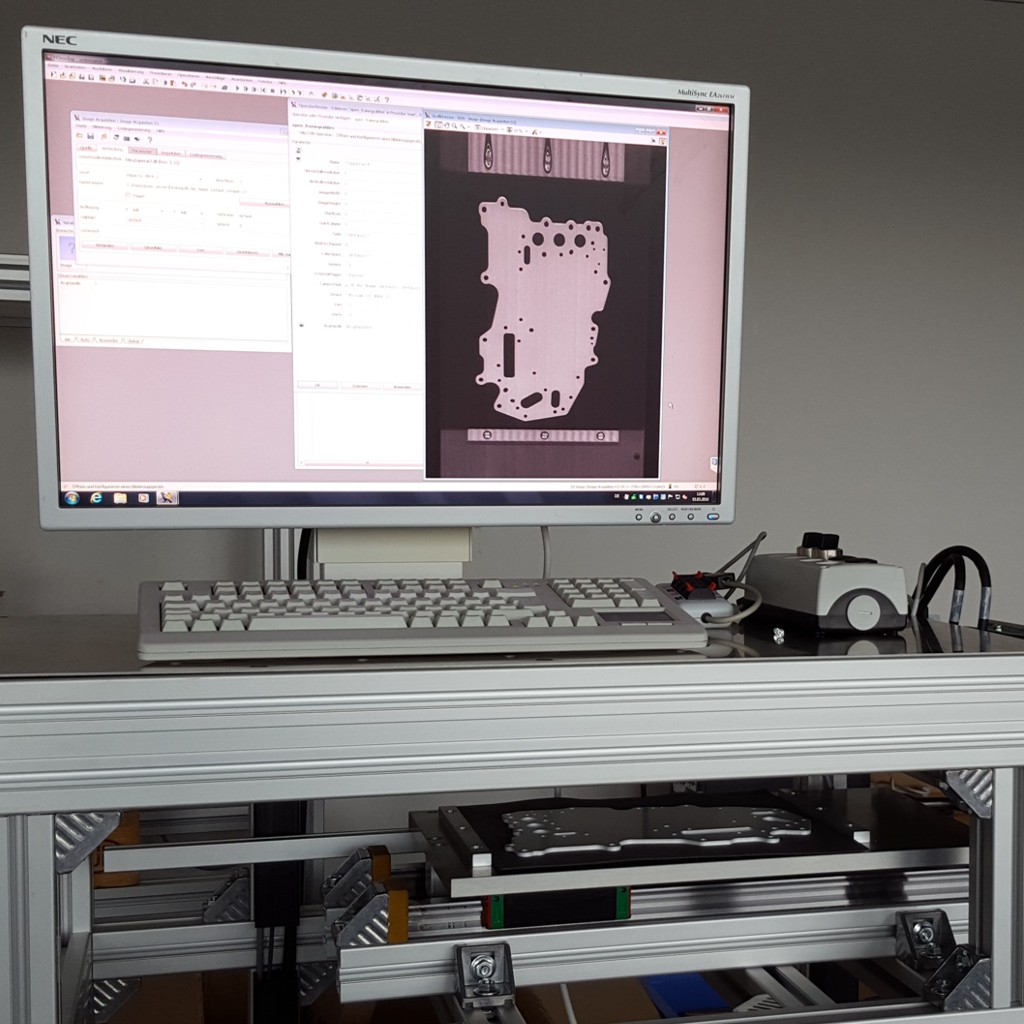

Camera applications are ideal for inspecting surfaces. The system automatically checks the condition of surfaces for predefined quality characteristics.

The fitting technology is chosen according to the requirements. Cameras scan the surface in either 2D or 3D. The control system evaluates the measured data and further processes them.

We use inline systems for inspection in high quality requirements on production lines.

With 3D scanning technology, we achieve high accuracy and reproducibility.

Assistance Systems

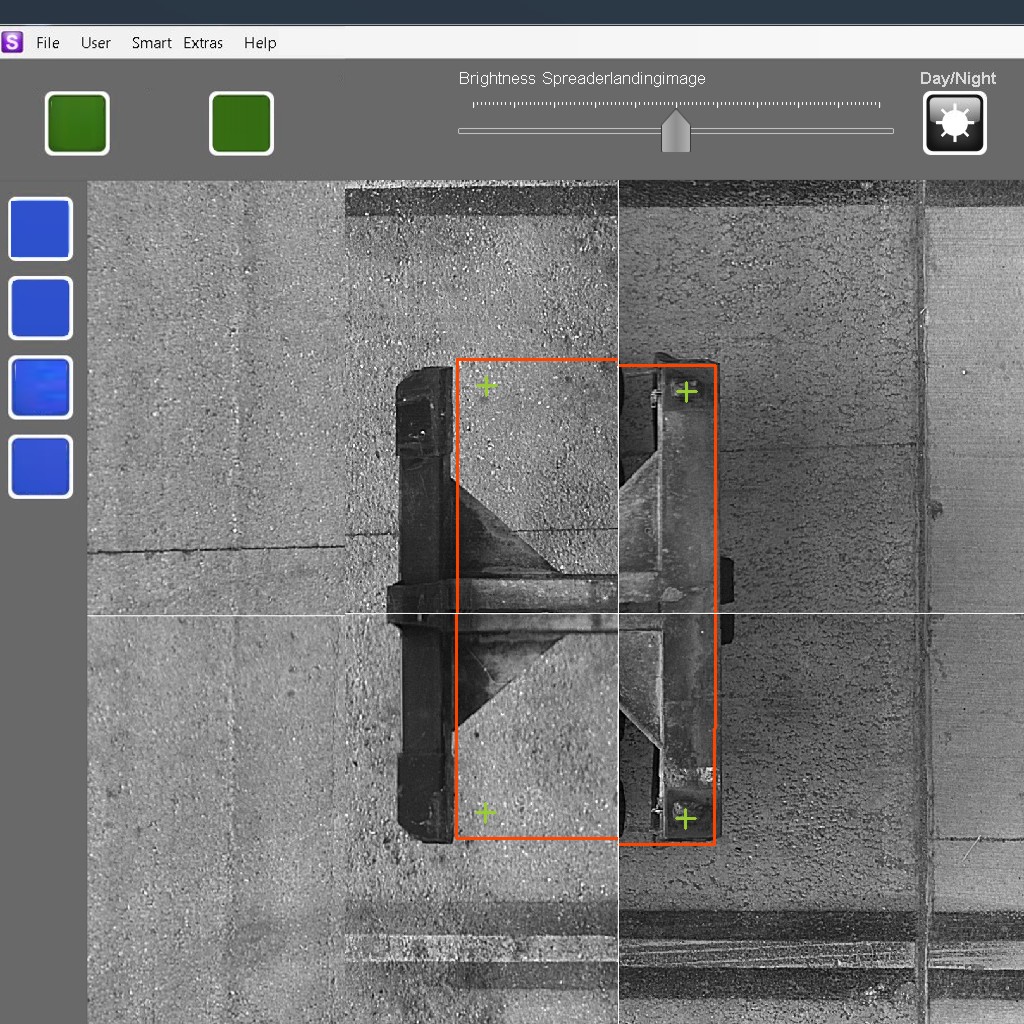

Assistance systems are used in applications where there is no insight into detailed process sequences, or when accuracy is required over a long distance.

Assistance systems are digital colleagues with a supporting role. The brand new technology “Augmented Reality” reflects digital information into reality.

These systems extend human perception and support, for example, the assessment of dangerous situations.

We are very successfully using assistance systems in lifting technology. The camera reliably spots in advance, what the human eye cannot capture from its perspective. The information, which is processed and then projected with actual data supplements the perception of man.

Object Measurement

Object measurement is about precise shape and size accuracy. The data capture is carried out with high-resolution 3D camera systems. The software automatically compares the 3D scan with the specifications from the CAD model.

For example, we use digital object measurement for automatic quality control. The quality assessment is fully automated using the CAD model.