control

Networked - Visualized - Decentralized - Notified

The IoT platform control is used where, where data must be visualized or managed securely and reliably.

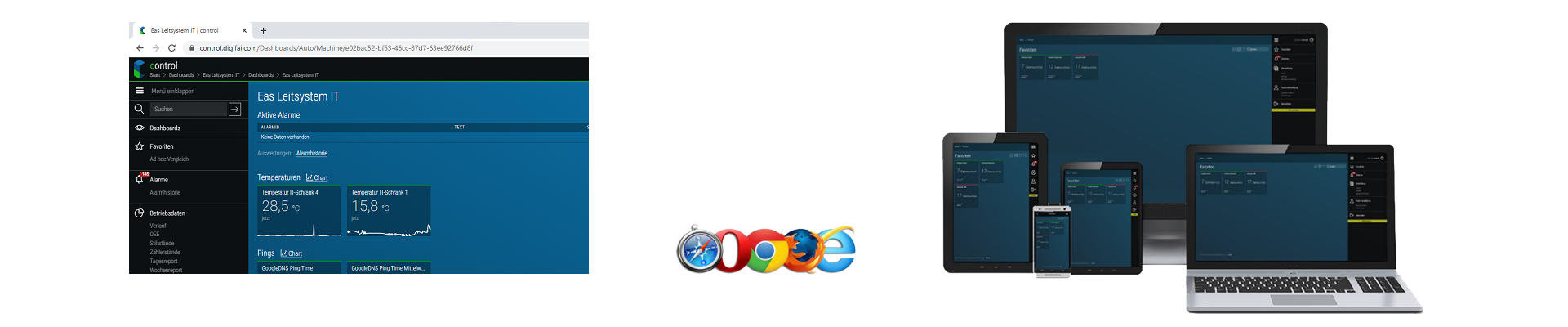

Machines, plants or buildings are connected to the control cloud server via secure connections. Visualization is decentralized via any browser-enabled end device..

control is not limited to one machine or plant section, it can be scalably placed over entire production lines or factories. control forms a stable basis for manufacturing solutions based on the principle of the Internet Of Things (IoT).

IoT platform control is online! More info on the product as well as on mobile monitoring of production machines, store floor data collection and machine metrics can be found at www.digifai.com

IoT Plattform control

control visualizes user-friendly – structures data and values

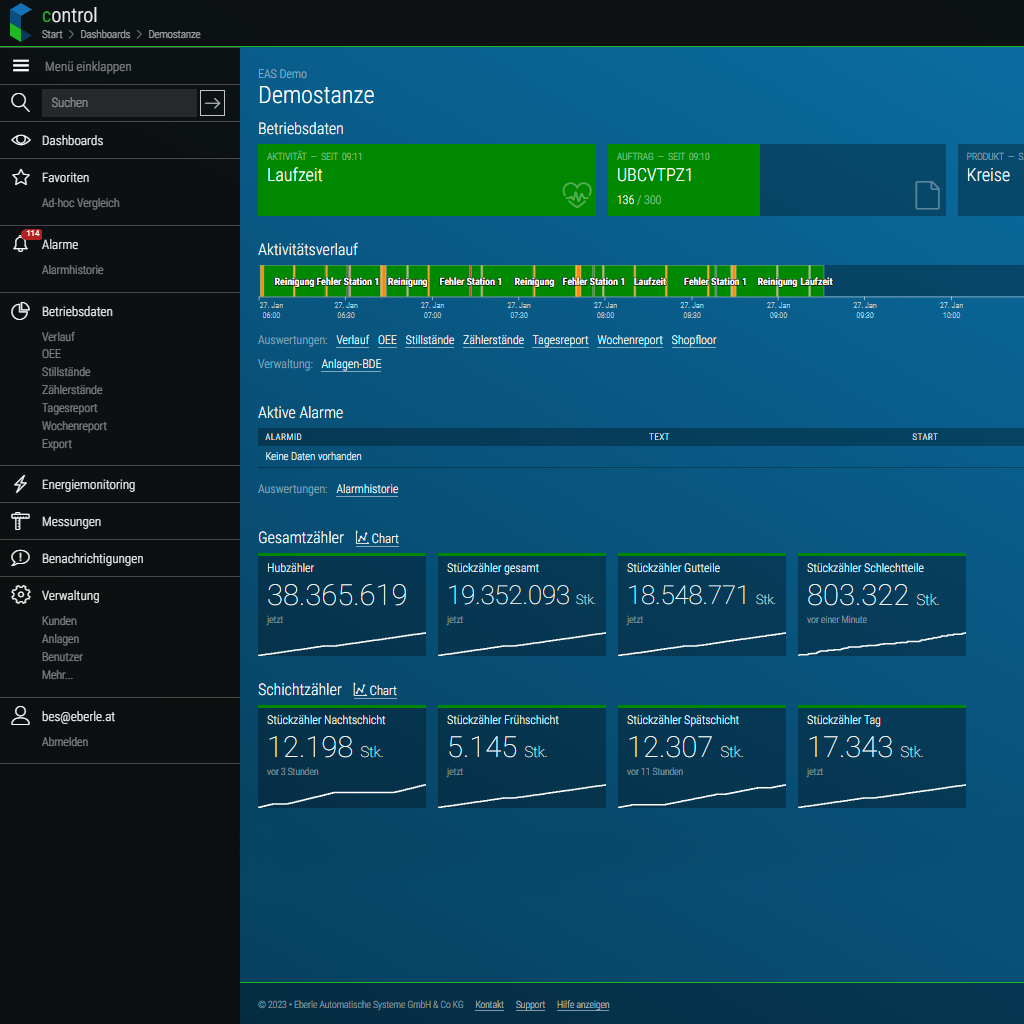

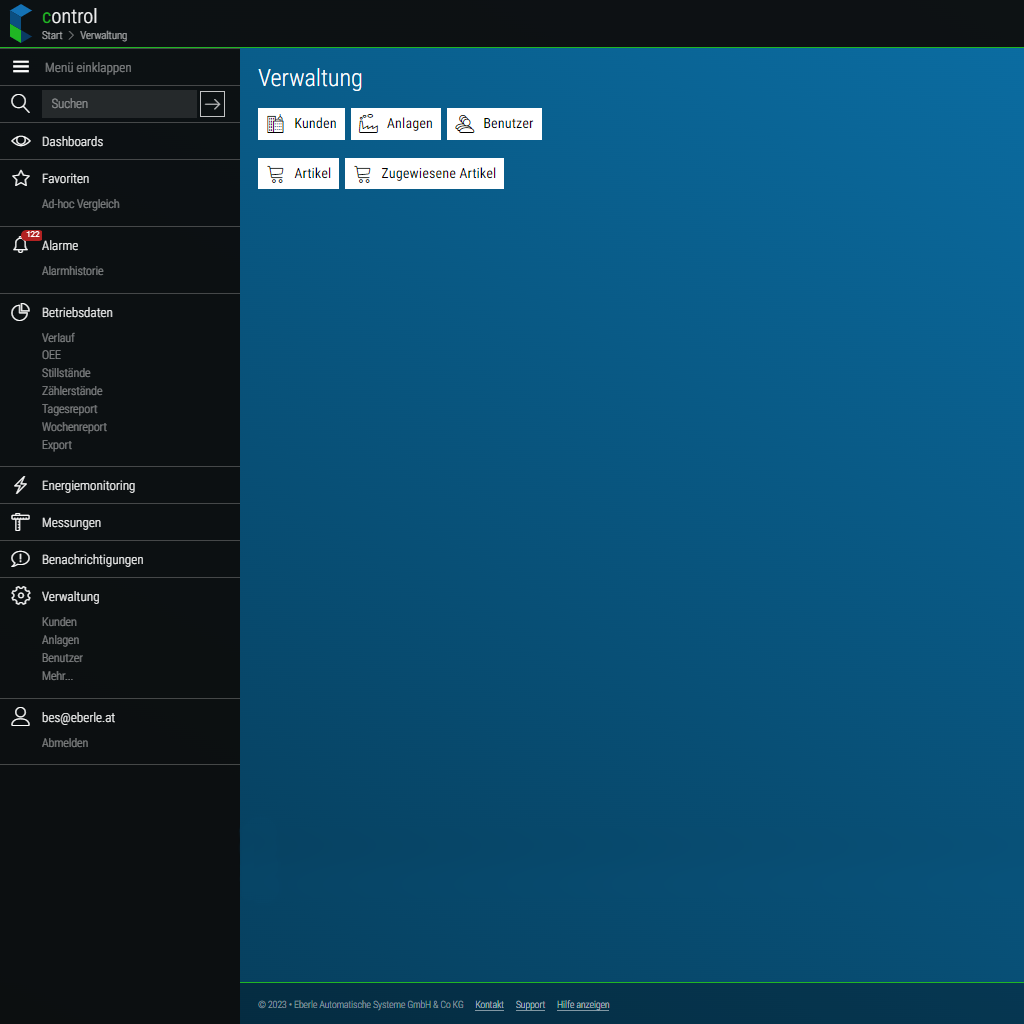

Modular and user-friendly control visualizes data in different views. Useful for control or evaluation, control provides segmented overview pages or detailed list views. By means of responsive user interfaces, clearly structured menu navigation and unambiguous symbolism, the displayed data is presented in a uniform manner. The user interface is multilingual, the texts come directly from the machine. This eliminates translation errors in the frontend and misleading terms.

control provides results for decisions

With control, plant data collection is automated. The values of piece counters, operating hours, production and downtimes are passed directly from the control level to control. The production data obtained in this way corresponds to the actual values and makes capacity information directly retrievable. The real data is available at any time and throughout the company for optimized work planning. On the basis of the real production data, accurate figures are obtained for a concurrent calculation, thus increasing the yield.

Operating messages, alarms and production data are displayed in user-defined views. The data is made available to the entire company through the cloud and can be used individually. Individual metrics are created in sets and organized into favorites. Properties and categorization of the messages are freely definable. Clear labeling and color coding enable intuitive operation on the mobile end device.

Watch and try

Nutzen Sie die Möglichkeit, die IoT Plattform control zu testenTake the opportunity, to test the IoT platform control!

With the demo version of control you get exclusive insights into the functionality and usability.

Simply request the demo installation, with your contact details, by emailing us.

control Service

control is a service with a comprehensive service package. Redundant and around the clock, the control Cloud is available. Maintained by a strong service team, the service is always up to date and is constantly being further developed. Thanks to the standardized browser solution, new functions are immediately available to everyone.

control in existing plants

control links to existing infrastructure and complements it where necessary. The platform of control is very flexible in the way of data integration. Customer-specific, it is first determined which data is needed and where it is already given in the installation. What is already available is also used. Data from existing control systems or PLC controls are taken over by control. If no measured value acquisition is available yet, Eberle Automatic Systems offers corresponding accessories.

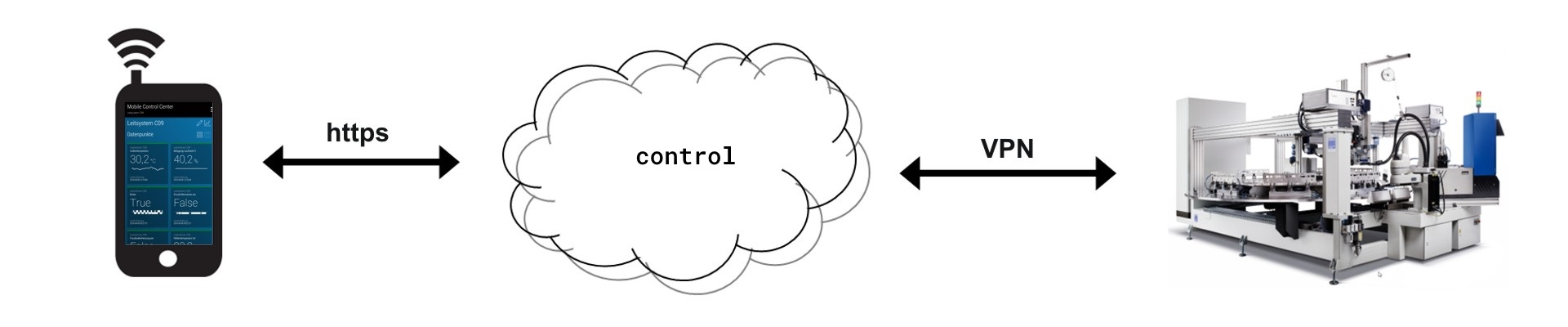

control connects securely

The IoT platform control is operated in a fully secured environment. Data exchange between the machine and the cloud takes place via a secure VPN connection with 128-bit encryption. Data is retrieved via a two-stage secured https browser session. In the backdesk of the control Cloud, specialists are continuously entrusted with monitoring security and ruling out attacks on the service. All this is done with a quality that is far above market standards.

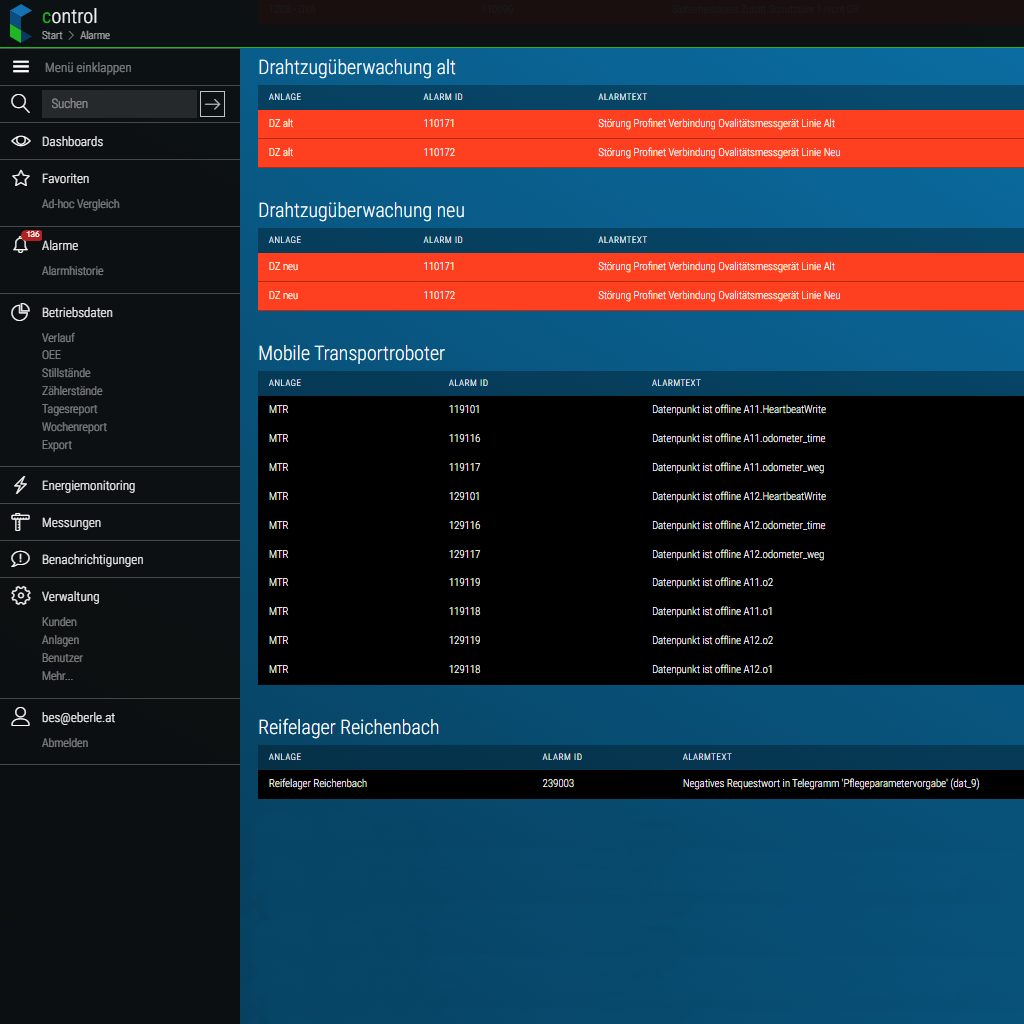

control monitors and notifies automatically

Automatically and in real time alarms are displayed in control. To make sure nothing goes wrong and to react safely and quickly in case of malfunctions, control provides several options to visualize and process alarms. Events can be configured as notification (SMS, e-mail).

Alarms can also be processed automatically in a defined procedure. control creates the optimal basis for this with its cloud solution.

control remembers everything and loses nothing

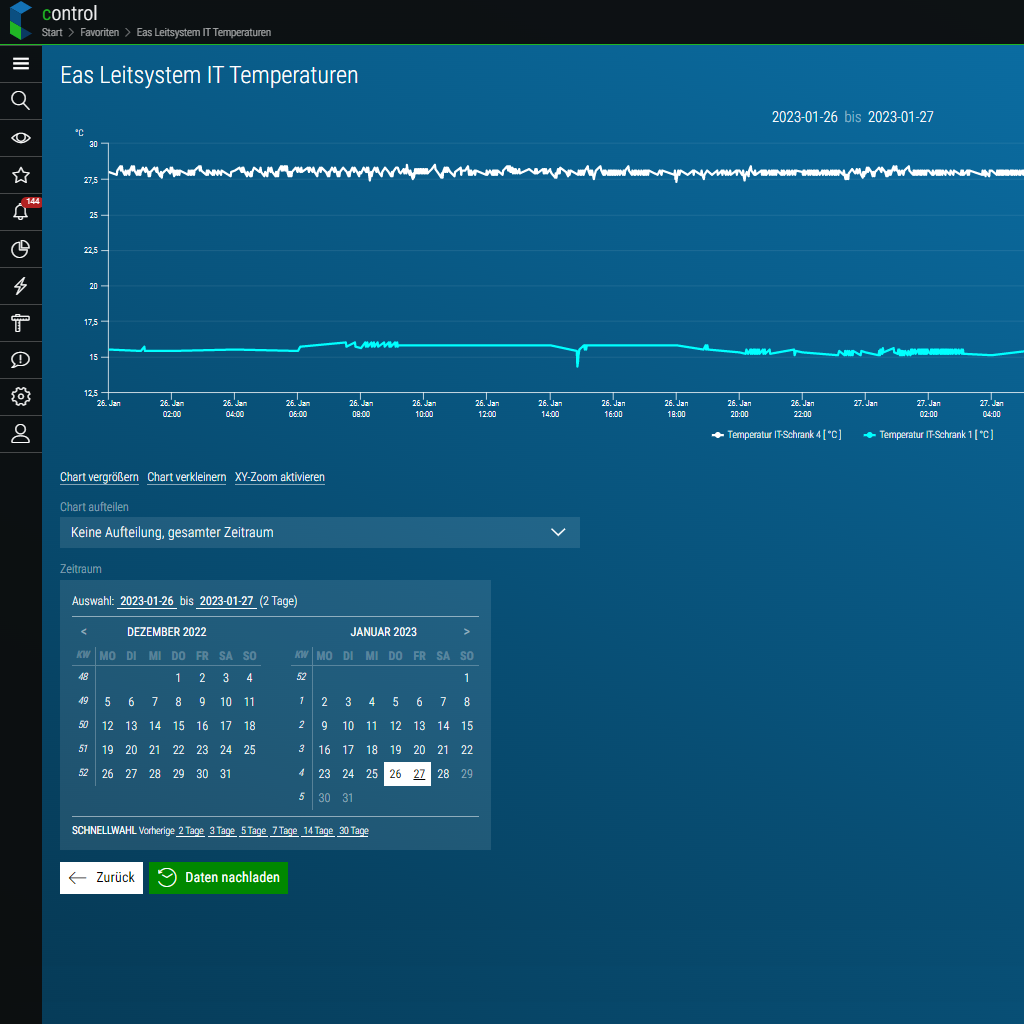

control is federated with a redundant cloud-based database and backs up data triggered by active events. This reduces data traffic to the essentials. This data can be securely retrieved at any time and is used for analysis in the event of plant-internal problems. With a zoomable trend function, data of a freely definable time period is displayed graphically. control thus becomes a tool in quality management.

control from machine to management

The architecture of control allows a very fine-grained user management. This is very specifically adjustable to the requirements of the respective operator. For example, the operating personnel can call up the current machine data in real time and the production manager monitors relevant production data globally.