Good Weather for Machines

It is generally known that the performance curve of the human organism is positively influenced in good weather. Absorption and concentration increase, the risk of illness decreases and a good mood motivates you to achieve top performance. Even minor malfunctions such as minimal injuries are easier to accept in good weather conditions. In any case, this applies to the human body, but what about machines? What weather does a machine need to produce at peak performance? Machines have no sense organs. They are in production and work according to their programming. If the parameters change, the system simply continues.

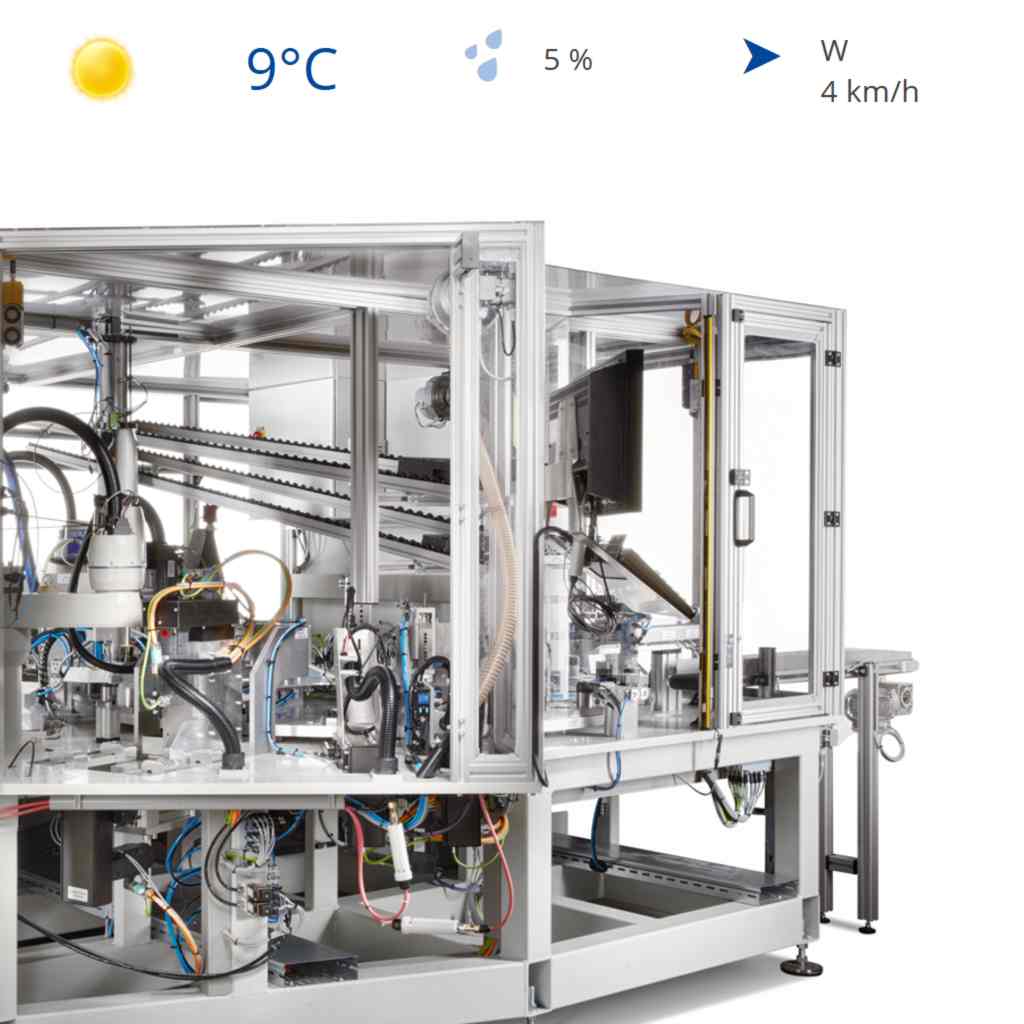

Machines in networked systems come a little closer to the human organism. With networked sensors and artificial intelligence, machines “experience” their environment and get an idea of their own condition. Through networking, they can make themselves felt and, for example, request help. Man, machine and resources communicate with each other in networked structures. For example, a “freezing” building in bad weather can start up the production facilities to heat with the waste heat from production. If a machine suffers from wear and uses predictive maintenance to recognize that maintenance is required, it can request help and at the same time report its own status to the process control. Production adapts to the new situation and reduces the throughput speed.

Machines and systems that think along with the production reduce errors and optimize the process. By intelligently linking ERP systems with the production level, the production control system responds directly to weather changes on the sales market. If the number of staff is reduced, the machine automatically adjusts the output. Using linked fitness data from the operating personnel, a system reacts in advance like an autopilot before a dangerous situation arises.

So that machines, systems and structures can react intelligently, they have to communicate with each other. The machine to machine (M2M) technology realizes such concepts. The generated data from machines, plants and structures are collected, compressed and processed. For this purpose, the sensors and actuators connect to a cloud, such as control, via their control system. The data is first saved and historically recorded. This creates large data silos with a lot of information. Big data solutions process this data using data mining and thus generate useful information for instructions. The cloud provides the information obtained where it is needed. The interaction of data, cloud and big data creates neural networks that react to environmental influences and can interact with other network participants. In good machine weather, the entire production runs at top performance. In the event of poor forecasts, intelligent production generates a strategy adapted to the situation.