Home

-

Automation is our world

-

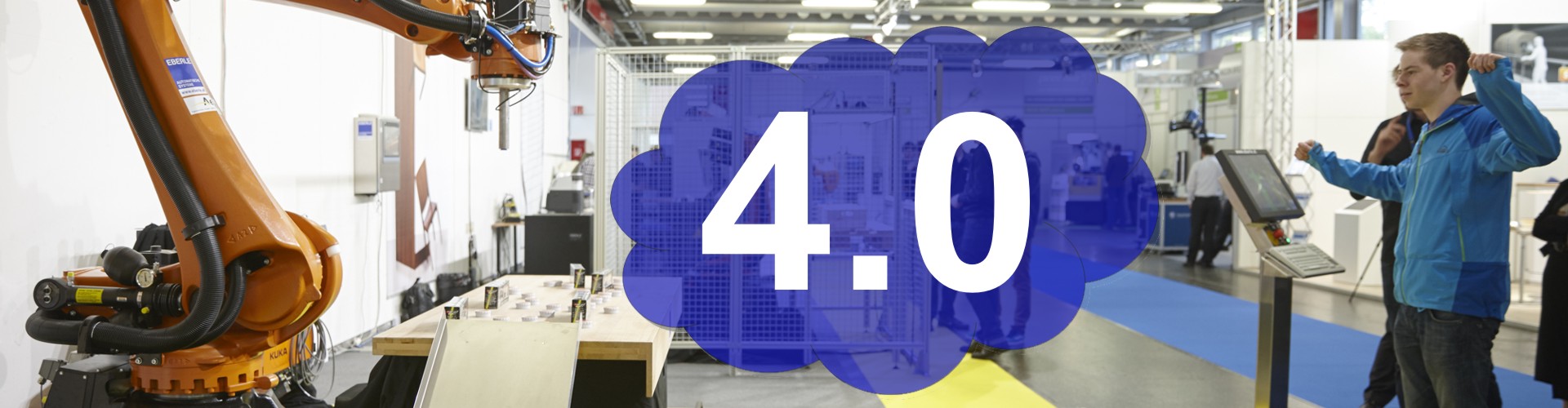

We deliver solutions for Industry 4.0

-

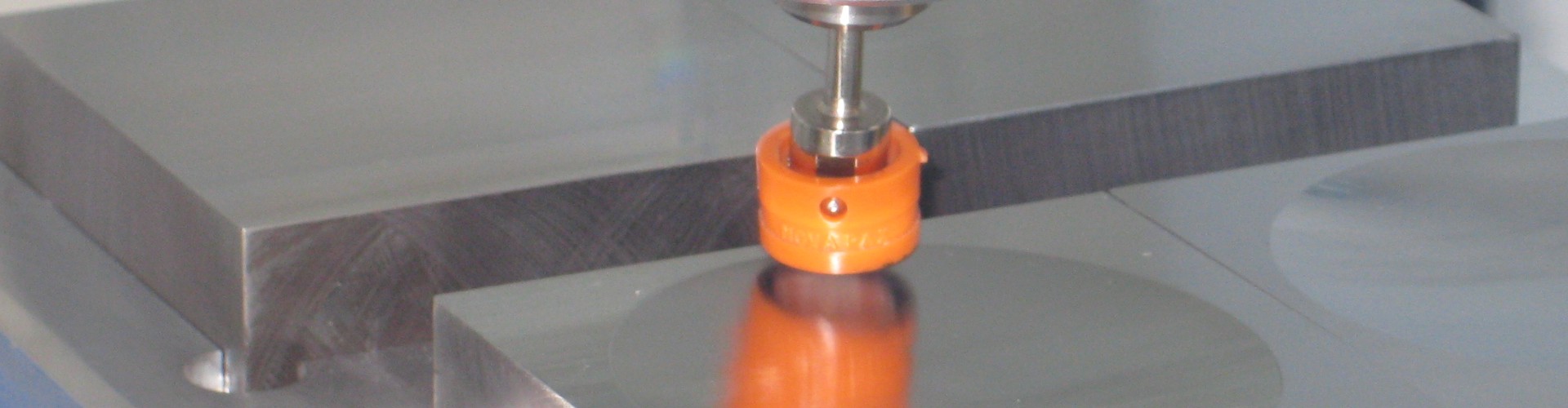

with clear focus and precision

-

with a motivated team

-

with a motivated team

-

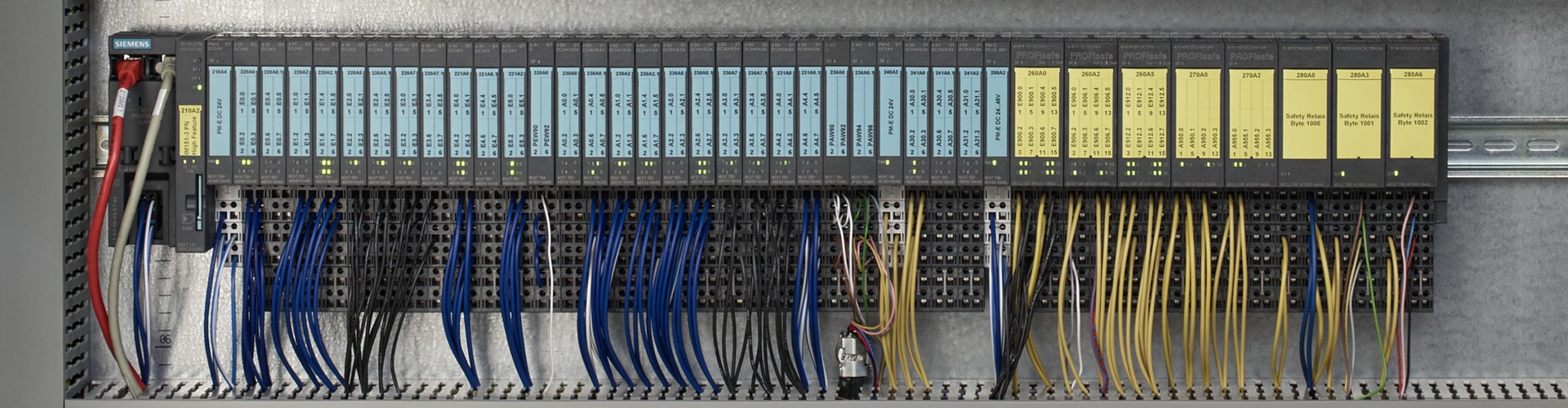

as a driving force in projects

-

with standardized modules

We are your partner for sophisticated automation technology

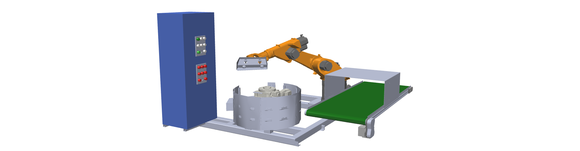

Roboterautomation

Human Robot Collaboration - Palletizing Systems - Machine Interlinking - Reach into the Box - Transport Robots

Mechanical Engineering

special machines - plant construction - plant tuning - dosing technology - retrofit - 4D planning

PLC system technology

Electrical Planning - PLC Software - Safety Software - Servo Drives - Distribution and Switchgear Construction - Commissioning

Industrial Image Processing

Quality Control - Object Recognition - Object Measurement - Surface Inspection - Augmented Reality

Process Monitoring - SCADA

Monitoring - Big-Data - Remote Solutions - 3D Visualization - HMI

IT Solutions

Industrie 4. 0 - Software - Hardware - Control Systems - Cloud Solutions - Virtual Commissioning